1․1 Fundamental Principles of Mechanics

The fundamental principles of mechanics form the cornerstone of understanding solid mechanics․ These principles include equilibrium conditions, stress-strain relationships, and the behavior of materials under various loads․ Key concepts such as axial loading, torsion, and bending are introduced to analyze how solids deform and withstand forces․ The relationship between external forces and internal reactions within a material is explored, emphasizing the importance of equilibrium in maintaining structural integrity․ These principles are mathematically described using equations of statics and material properties like elastic modulus and Poisson’s ratio․ Understanding these fundamentals is crucial for predicting how materials behave under different conditions, ensuring safe and efficient engineering designs․ Textbooks like “Mechanics of Solids” by R․K․ Bansal provide detailed explanations and practical examples to master these principles․

1․2 Importance of Mechanics of Solids in Engineering

Mechanics of Solids is a cornerstone of engineering, enabling the design and analysis of structures, machines, and materials․ Understanding how solids behave under stress, strain, and deformation is critical for ensuring the safety and efficiency of engineering projects․ This knowledge allows engineers to predict material failure, optimize designs, and select appropriate materials for specific applications․ It is essential for fields like aerospace, civil, and mechanical engineering, where structural integrity and material performance are paramount․ By studying mechanics of solids, engineers can develop innovative solutions to real-world problems, ensuring that structures and devices withstand operational loads without failure․ Textbooks like “Mechanics of Solids” by Carl T․ F․ Ross provide comprehensive resources for mastering these principles, making them indispensable for engineering education and practice․

Key Concepts in Mechanics of Solids

Mechanics of Solids introduces fundamental concepts like stress, strain, torsion, bending, shear force, and bending moments, essential for analyzing deformation and failure in engineering materials and structures․

2․1 Stress and Strain

Stress and strain are foundational concepts in mechanics of solids, describing how forces applied to a material cause deformation․ Stress is the internal force per unit area, measured in pascals (Pa) or pounds per square inch (psi), and can be tensile, compressive, or shear․ Strain represents the resulting deformation, expressed as a dimensionless ratio of the change in length to the original length․ Elastic materials exhibit linear elastic behavior, where stress and strain are proportional (Hooke’s Law), while plastic materials deform permanently․ The stress-strain diagram illustrates this behavior, showing the elastic limit, yield point, ultimate strength, and failure․ Understanding stress-strain relationships is critical for predicting material failure and designing structures to withstand external loads without excessive deformation or fracture․

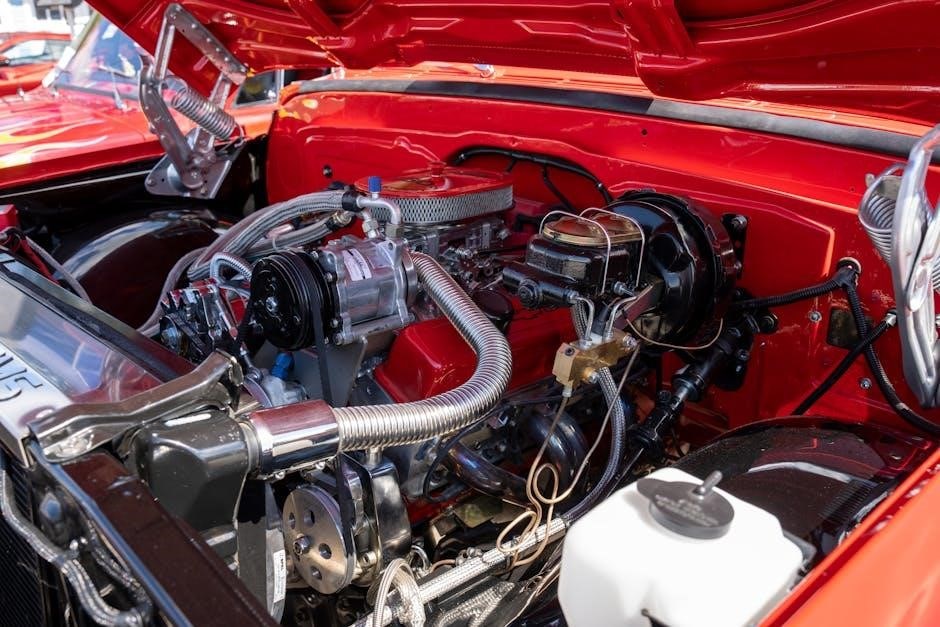

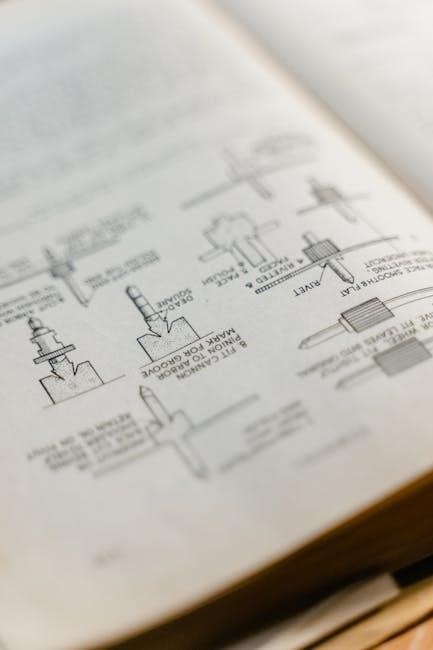

2․2 Torsion and Bending

Torsion and bending are critical loading conditions in mechanics of solids, often encountered in beams, shafts, and structural members․ Torsion occurs when a twisting force is applied, creating shear stresses that vary across the cross-section․ Bending, on the other hand, results from transverse loads, producing a combination of tensile and compressive stresses․ The torsion formula involves the torsion constant and shear modulus, while bending moment equations incorporate the moment of inertia and modulus of elasticity․ These concepts are essential for designing components like engine shafts and bridges, ensuring they can withstand twisting and bending forces without failure․ Understanding torsion and bending is vital for analyzing structural integrity and predicting deformation under various loads․

2․3 Shear Force and Bending Moment

Shear force and bending moment are essential concepts in analyzing the behavior of beams and structural members under transverse loads․ Shear force is the internal force that causes a material to deform by sliding along a plane, while bending moment is the internal torque that causes bending․ Both are critical for determining the stress distribution and deformation in beams․ Engineers use shear force diagrams and bending moment diagrams to visualize these forces along the length of a member․ Understanding these concepts is vital for designing safe and efficient structures, as excessive shear force or bending moment can lead to material failure․ Accurate calculations of these forces ensure structural integrity under various loading conditions․

Stress-Strain Relationships

Stress-strain relationships describe how materials deform under load, linking stress to strain․ Elastic modulus defines stiffness, while Poisson’s ratio relates lateral and axial strains․ These principles are fundamental for analyzing material behavior under various loading conditions and are essential in engineering design to predict structural performance and safety margins․ Understanding these relationships helps engineers select appropriate materials and design components that can withstand expected stresses without failure․

3․1 Elastic Modulus and Poisson’s Ratio

The elastic modulus, or Young’s modulus, measures a material’s stiffness and is defined as the ratio of stress to strain within the proportional limit․ It indicates how easily a material deforms under stress․ Poisson’s ratio describes the lateral strain response to axial loading, providing insight into a material’s lateral deformation characteristics․ Both properties are essential for understanding elastic behavior and are used in engineering design to predict how materials will respond to external forces․ These ratios are critical in analyzing beams, columns, and other structural elements, ensuring designs are safe and functional․ They are fundamental parameters in stress-strain relationships, enabling accurate predictions of material performance under various loading conditions․

3․2 Yield Strength and Ultimate Tensile Strength

Yield Strength is the stress at which a material begins to deform plastically, meaning it will not return to its original shape when the load is removed․ Ultimate Tensile Strength (UTS) is the maximum stress a material can withstand while being stretched or pulled before failing or breaking․ Both properties are critical in engineering for material selection and design, ensuring structures can handle expected loads without permanent deformation or catastrophic failure․ Yield Strength helps design structures that resist plastic deformation under normal conditions, while UTS ensures materials can endure extreme stresses․ These properties are typically determined through tensile testing, which involves pulling a material sample until it breaks and recording stress at critical points․

3․3 Modulus of Resilience and Toughness

Modulus of Resilience is the energy a material can absorb without permanent deformation, representing its capacity to store elastic energy․ It is calculated as the area under the stress-strain curve up to the yield point․ Toughness, on the other hand, measures the total energy a material can absorb until fracture, including both elastic and plastic deformation․ It is determined by the area under the entire stress-strain curve․ Both properties are crucial for assessing a material’s ability to withstand loading and impact․ Modulus of Resilience is vital for applications requiring energy storage, while Toughness is essential for materials subjected to sudden impacts or extreme stresses, ensuring structural integrity in real-world engineering scenarios․

Loading Conditions in Solids

Loading conditions in solids involve external forces that induce stresses, strains, and deformations․ Common types include axial, torsional, bending, and thermal loads, crucial for engineering design and analysis․

4․1 Axial Loading

Axial loading refers to forces applied along the length of an object, causing it to stretch or compress․ It involves tension or compression forces acting parallel to the longitudinal axis․ This loading condition is fundamental in analyzing structural components like rods, bars, and columns․ Axial loading induces uniform stress and strain across the cross-sectional area when the force is evenly distributed․ The stress (σ) is calculated as force divided by area (σ = F/A), and strain (ε) is the deformation per unit length (ε = ΔL/L)․ Understanding axial loading is crucial for designing elements subjected to direct tension or compression, such as cables and pillars․ It forms the basis for more complex loading scenarios in engineering applications․

4;2 Thermal Stresses

Thermal stresses arise due to temperature changes in a material, leading to expansion or contraction․ When a material is heated, it expands, and when cooled, it contracts․ If the material is restrained or cannot move freely, internal stresses develop․ These stresses can cause deformation, cracking, or failure․ The thermal expansion coefficient (α) determines the magnitude of expansion or contraction․ In engineering, thermal stresses are critical in structures exposed to varying temperatures, such as engines, pipelines, and aerospace components․ Proper material selection and design are essential to mitigate these stresses․ Understanding thermal stresses ensures the reliability and safety of structures under thermal loads, preventing potential failures․ This concept is vital in mechanical and civil engineering applications․

Engineering Materials and Their Properties

Engineering materials, like metals, polymers, and composites, exhibit unique properties such as strength, ductility, and stiffness, critical for structural and mechanical applications in engineering design․

5․1 Metals and Their Mechanical Properties

Mechanical properties of metals, such as strength, elasticity, and plasticity, are critical in engineering applications․ Metals like steel and aluminum exhibit high strength-to-weight ratios, making them ideal for structural designs․ Properties like ductility and hardness determine their suitability for various loading conditions․ Elasticity allows metals to return to their original shape after deformation, while plasticity enables permanent deformation without fracture․ These properties are influenced by the material’s crystal structure and alloying elements․ Understanding these characteristics is essential for selecting appropriate metals in engineering projects, ensuring safety, and optimizing performance under different stress and strain conditions․ This section provides a detailed overview of the mechanical properties of metals and their relevance in solid mechanics․

5․2 Polymers and Composites

Polymers and composites are versatile engineering materials with unique mechanical properties․ Polymers, such as plastics and elastomers, exhibit viscoelastic behavior, combining viscous and elastic characteristics․ They are lightweight, corrosion-resistant, and ideal for applications requiring flexibility․ Composites, like fiber-reinforced polymers, combine materials to achieve enhanced strength, stiffness, and durability․ Their anisotropic properties allow for tailored designs, making them suitable for aerospace and biomedical applications․ Understanding their stress-strain relationships, creep resistance, and fatigue behavior is essential for design optimization․ This section explores the mechanical properties of polymers and composites, highlighting their advantages and limitations in various engineering contexts․ It also discusses advancements in material science that expand their applications in modern industries․

Textbook Recommendations

Popular Mechanics of Solids textbooks include Hibbeler and Beer/Johnston, offering comprehensive coverage and practical examples․ Both are trusted resources for students and professionals alike․

6․1 Popular Textbooks for Mechanics of Solids

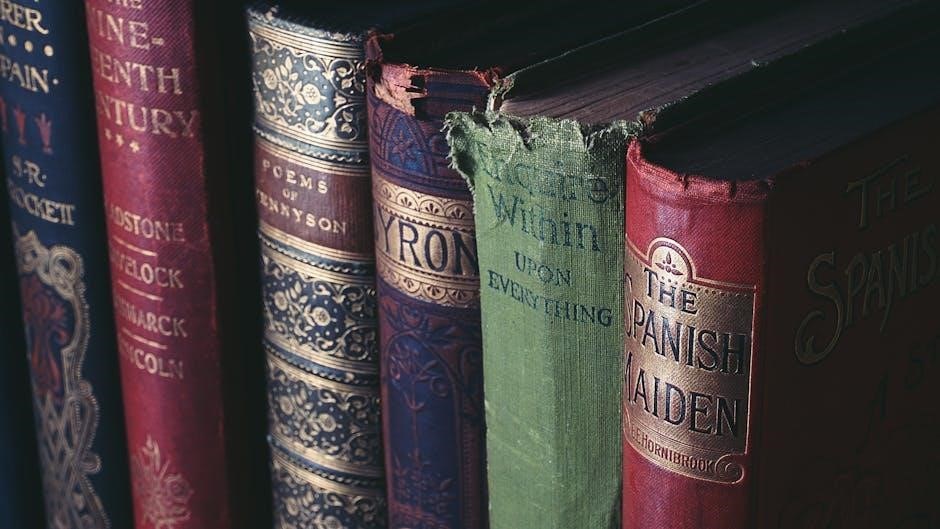

Several textbooks are widely recognized for their comprehensive coverage of mechanics of solids․ Among the most popular are “Mechanics of Solids” by E․J․ Hearn, “Mechanics of Materials” by R․C․ Hibbeler, and “Mechanics of Solids” by S․P․ Timoshenko․ These texts provide detailed explanations of stress, strain, torsion, and bending, along with practical examples and problems․ Hibbeler’s text is noted for its clear explanations and extensive problem sets, making it a favorite among students․ Similarly, Beer and Johnston’s “Mechanics of Materials” is praised for its logical structure and real-world applications․ These textbooks are often available in PDF format, making them accessible for digital learners․ They remain essential resources for understanding the fundamentals of solid mechanics․

6․2 Comparison of Hibbeler and Beer/Johnston Textbooks

The Hibbeler and Beer/Johnston textbooks are two of the most widely used resources for mechanics of solids․ Hibbeler’s text is known for its detailed problem sets and clear, step-by-step explanations, making it ideal for students who prefer a hands-on learning approach․ In contrast, Beer/Johnston focuses on fundamental concepts and real-world applications, offering a more theoretical foundation․ Both texts cover essential topics like stress, strain, and torsion, but Hibbeler’s emphasis on practical problems makes it popular among engineering students․ Beer/Johnston, on the other hand, is often praised for its logical structure and ability to connect theory to practice․ Both are available in PDF formats, catering to different learning styles and preferences․

Accessing Mechanics of Solids Textbook in PDF

Accessing mechanics of solids textbooks in PDF format is convenient for students and professionals․ Popular platforms like Amazon, Google Books, and university libraries offer digital versions for easy access and study․

7․1 Sources for Downloading the Textbook

Several platforms provide access to mechanics of solids textbooks in PDF format․ Amazon and Google Books offer digital versions for purchase or preview․ University libraries often subscribe to platforms like Springer and ScienceDirect, which host eBooks for students․ OpenStax and other open educational resources offer free, high-quality textbooks․ Additionally, websites like PDFDrive or Library Genesis may have downloadable versions, though users should verify legality․ Always ensure downloads comply with copyright laws and institutional policies to avoid infringement․ These sources cater to diverse learning needs, offering convenience and accessibility for students and professionals alike․ Exploring these options can help users find the most suitable resource for their studies or work․

7․2 Legal Considerations for PDF Downloads

Downloading mechanics of solids textbooks in PDF format requires careful consideration of copyright laws․ Many textbooks are protected by copyright, and unauthorized downloads from unofficial sources may constitute infringement․ Always ensure that the source is legal, such as purchasing from official publishers or accessing through university subscriptions․ Platforms like Amazon, Pearson, and McGraw-Hill offer legitimate digital copies․ Using unauthorized websites or file-sharing platforms can lead to legal consequences․ Respect intellectual property rights by obtaining materials through lawful channels․ Libraries and educational institutions often provide access to eBooks legally, ensuring compliance with copyright regulations․ Prioritize legal methods to avoid penalties and support authors and publishers․ This approach promotes ethical academic and professional practices․

Mechanics of Solids is a foundational engineering discipline, providing essential tools for analyzing structural integrity and material behavior․ Its principles are vital for designing safe and efficient systems․

8․1 Summary of Key Concepts

Mechanics of Solids provides a comprehensive understanding of stress, strain, and deformation in materials under various loads․ Key concepts include stress-strain relationships, elastic modulus, and Poisson’s ratio, which define material behavior․ Torsion, bending, and axial loading principles are essential for analyzing structural integrity․ Shear force and bending moments are critical in predicting failure points․ Yield strength and ultimate tensile strength determine material limits, while modulus of resilience and toughness measure energy absorption capabilities․ These principles, along with thermal stresses, are vital for designing safe and efficient engineering systems․ Understanding these concepts ensures accurate predictions of material performance under real-world conditions․

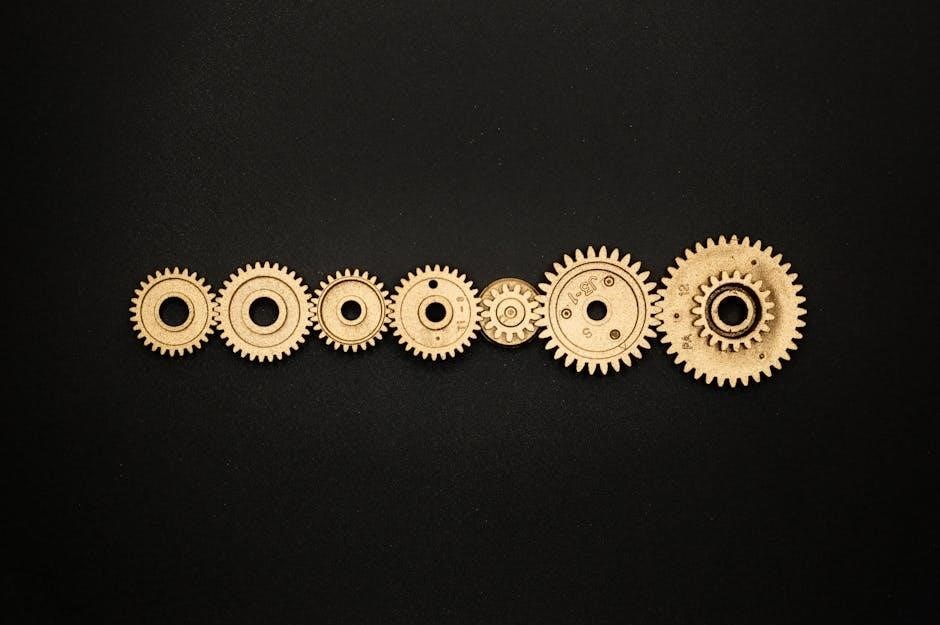

8․2 Applications of Mechanics of Solids in Real-World Engineering

Mechanics of Solids is foundational in designing and analyzing structural components across various engineering disciplines․ In civil engineering, it ensures bridges and buildings withstand external loads․ Mechanical engineers apply these principles to design machinery, engines, and gears․ Aerospace engineering relies on stress-strain analysis for lightweight, durable aircraft and spacecraft components․ Biomedical engineers use these concepts to develop prosthetics and medical devices․ Additionally, consumer product design benefits from understanding material behavior under torsion and bending․ Renewable energy systems, such as wind turbines, also depend on these principles to optimize performance and safety․ By applying mechanics of solids, engineers create efficient, reliable, and safe solutions for real-world challenges․